We explore the process in detail how human hair is sourced, processed, and fitted to a variety of wig cap designs to create high-quality wigs for the discerning customer.

Human Hair wigs are not new and have been adorning the heads of fashionable ladies for centuries and although the basic wig construction techniques have remained somewhat unchanged for many years, new advances in coloring and wig cap design have revolutionized the industry. “How are Human Hair Wigs Made?” will explore the process by which human hair is sourced, processed, and fitted to a variety of wig cap designs to create high-quality wigs for the discerning customer.

Table of Contents

-

Human Hair Wigs

- Sourcing: Where does Human Hair come from?

- Processing: How is Human Hair processed?

- Coloring Options for a Human Hair Wig

- Wig Manufacturing: How Is a Wig Made?

- The Wig Cap

- Wig Cap Components:

- Ventilating a Wig Cap

- Styling Wavy/Curly Wigs

- Distribution: Wigs Boxed and Shipped

- The Pros and Cons of Human Hair

- Summary

Related: 13 Different Types of Wigs to Choose From (Your Wig Guide) | 50 of the Best Online Wig Stores – Where to Buy Good Wigs on the Web

Human Hair Wigs

Human Hair has become the fiber of choice for high-quality wigs, hairpieces, and extensions because of its superior look, feel and movement being so close to biological hair. Throughout history, both horsehair and yak hair has been used in wig making because of their ability to hold a curl and therefore maintain styling. This hair, however, is coarse, thick, and uncomfortable and early Italian wig designers opted for human hair as a better medium. Today, human hair represents a $5 billion market that is truly global in nature and like most supply chains includes multiple stages:

- Harvesting/Sourcing of Human Hair Fiber

- Sorting and Processing Human Hair

- Assembly/Manufacturing of the Wig or Hairpiece

- Distribution

Sourcing: Where does Human Hair come from?

The Human Hair market is a global market that continues to expand annually driven by soaring demand for wigs and extensions in Western Europe and the United States. Over 70% of human hair today originates from either China or India but recent increases have been seen in South America (Brazil and Peru) and also in Eastern Europe (Russia). Quality varies and harvesting practices have come under scrutiny as large wig manufacturers seek to manage their supply chains and promote ethically sourced fiber with known origin and quality.

The most sought after human hair fiber is that which has been obtained voluntarily, which is harvested from a single donor and which has not been dyed, treated or processed previously. (Remy Human Hair). One major source of Human Hair is the Hindu temples in Southern India, where pilgrims sacrifice their hair in a practice called tonsuring. According to ancient scriptures all Hindus are required to voluntarily shave their heads at least once in their lifetime. At the Venkateswara Temple, in Tirumala, more than 1,300 barbers shave an average of 40 heads per day and the hair is sold to merchants at auction for distribution around the world. The quality, reliability and ethical sourcing of this fiber make this highly desirable. In China, Human Hair Merchants gather at auctions like the Fuchun Hair Market to buy and sell raw human hair fiber that has been tied into ‘hanks’ or bundles. Trades amount to millions of dollars per day as professional buying agents seek out quality and reject poor quality fiber lots.

Eastern European Human Hair is considered to be the most prized of all. Genetics, lifestyle and diet make this the best hair in the world owing to it’s healthy appearance, strength and natural blonde/brown coloring. This is gathered at ‘hair fairs’ where agents will bid for hair and shave it after a deal has been struck. Hair sold voluntarily for reimbursement is considered ‘ethically sourced’.

There is an unscrupulous side to this trade that preys on the poor and disadvantaged around the world and peddles mixed fiber of unknown origins that has been chemically treated. Human Hair, because of its value, can be shaved involuntarily which does not qualify as ‘ethically sourced’. Large corporations like Aderans (Noriko and Rene of Paris), HairuWear (Raquel Welch and Gabor), and Jon Renau invest heavily in establishing ethical sourcing practices that ensure the best quality fiber with an established chain of custody.

Processing: How is Human Hair processed?

Human hair fiber is generally purchased in unprocessed and unwashed bundles and needs to be sorted and processed before moving onto the wig assembly stage.

- Presorting. Bundles from the auctions are unwrapped and sorted to ensure that foreign bodies (bugs) are removed, white or grey hairs are removed and that all cuticles in the lot run in the same direction. The hair will frizz uncontrollably during washing if the fibers do not run in the same direction.

- Washing and Disinfecting. All fibers are washed and disinfested and dried with specific care not oversoak, which will strip valuable oils from the human hair. Drying is usually outdoors for a couple of hours with particular care taken not to dry the hairs out and make them brittle.

- Sorting the Short Hairs. Using an apparatus called a hackle, the hair bundle is pulled through a series of spikes repeatedly in order to remove the shorter hairs (those less than 3”). Almost identical to the hackles used in the 15th century to sort flax and hemp, the hackles of the modern hair industry have not changed much. The hackle removes the short hairs which would cause

- Shedding is left as part of the bundle. When complete the hair fibers in the bundle are then secured and tied with a string and then washed again.

- Sorting for Length. The dried bundles are returned to the hackle for straightening and the fibers are sorted into lengths using wire drawing brushes. Sorting for length is critical later for wig manufacturers to select certain fiber lengths for different styles.

- Coloring. The human hair is processed by lightening the hair to the highest level prior to depositing textile-like hair dyes to achieve a specific color. Chemicals are used to first strip pigmentation from the fibers and then the dyes are applied to create the pre-defined colors. Once complete, hair fiber of the same or different lengths can now be combined or blended to the exact specifications of the wig maker.

- Silicone applied. The last step is for the human hair bundles to receive a fine layer of silicone before advancing to the next step. This holds in the color, the moisture, and the smooth texture and will disappear shortly after early wear.

- Machine sowed into Wefts. In some cases, individual fibers are used for assembly into a wig and in some cases, wefts of human hair are used. What is a Human Hair Weft? A weft is a thin strip onto which individual hair strands are attached. The strip lengths are sown up to 3 times for reinforcement and to avoid fiber shedding once applied to a wig cap. These wefts can be used on certain parts of the wig cap and are obviously faster and cheaper to create because they are machine-made.

In most cases, the human hair wefts and bundles are now moved from the hair factory to the wig manufacturing location for final assembly into finished products.

Coloring Options for a Human Hair Wig

Customers want real-life coloring options in their wigs in the same way as they want them from their colorist at the salon. Manufacturers have responded with a broad spectrum of color options for each of their human hair wigs and in some cases, there can be 25-30 color options for each wig style. During the manufacturing process, strict instructions are given for each color option and the blending of each to form the final bundle of weft used to make the final wig. Each manufacturer has developed a systematic approach to help categorize their colors. In the case of Jon Renau, the approach starts with an industry-standard spectrum of base color levels that range from black through brunette, blonde, red, and grey/platinum. Each level is represented by a number.

What are Color Levels?

Color Codes – Variants:

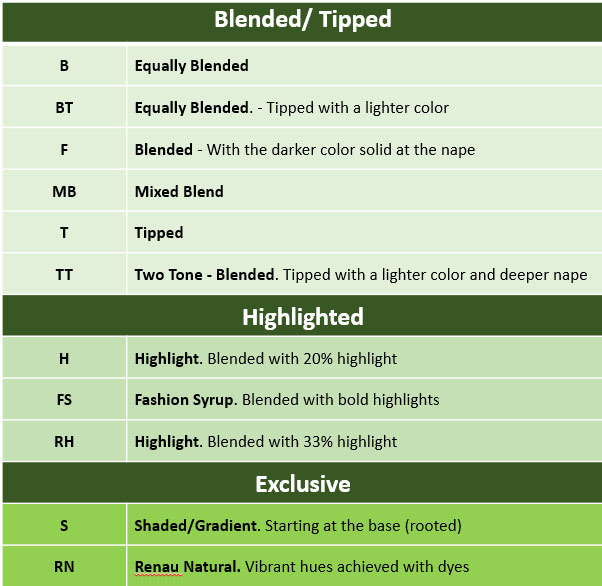

Given that bio hair is made up of a number of different colors in a blend and more recent trends in hair coloring have adopted gradients, highlights, and shading, it is necessary to go beyond the base color levels to create these blends. This is where the color coding comes in. Jon Renau has categorized their coding and color variants into 3 color families. Blended + Tipped, Highlights, and Exclusive.

Base Color plus the Variant:

The final stage in the Jon Renau Color Coding Process is to tie the color levels with the color codes. The first number identifies the base color and the following color codes will identify the blend or highlight.

Wig Manufacturing: How Is a Wig Made?

A wig is assembled from various different components according to the wig designer’s specifications. The wig cap and the human hair wefts or fiber bundles come together to form the finished product. In most cases, this is a separate operation from the hair factory. A large amount of wig manufacturing takes place in China but some of the major wig labels have moved their wig factories to Thailand (Aderans) or Indonesia (HairuWear and Jon Renau)

The Wig Cap

The Wig Cap is the underlying exoskeleton of the wig and defines the fit, function, and look of the final product. There are many different components of the wig cap that designers can bring together based on their objective and price point of the style. Human hair fiber is attached to each of these wig cap components to create different styling options and features.

Wig Cap Components:

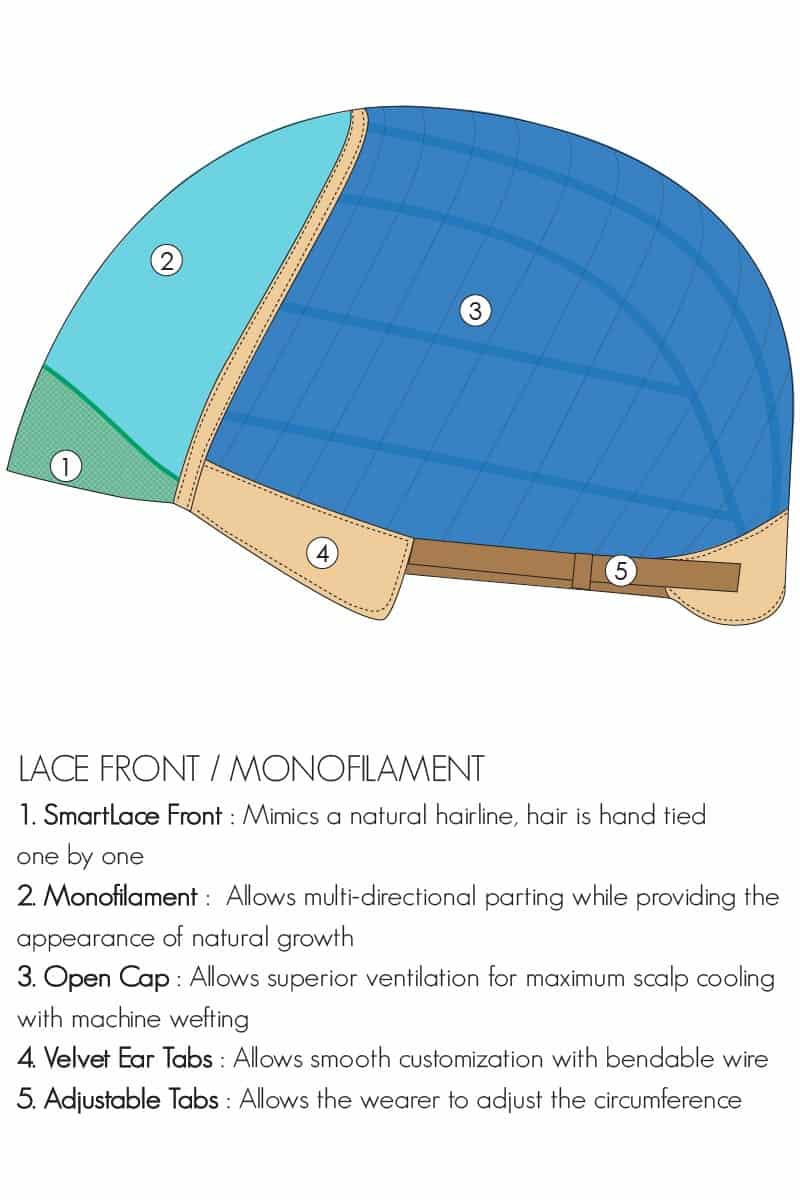

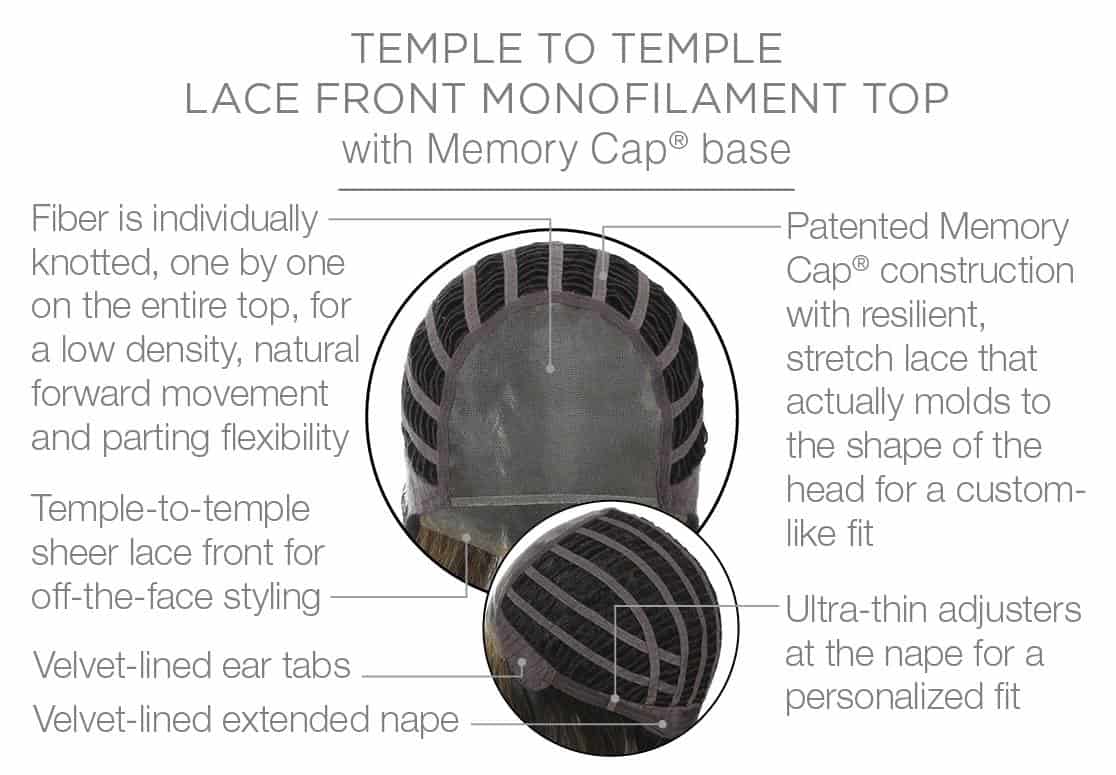

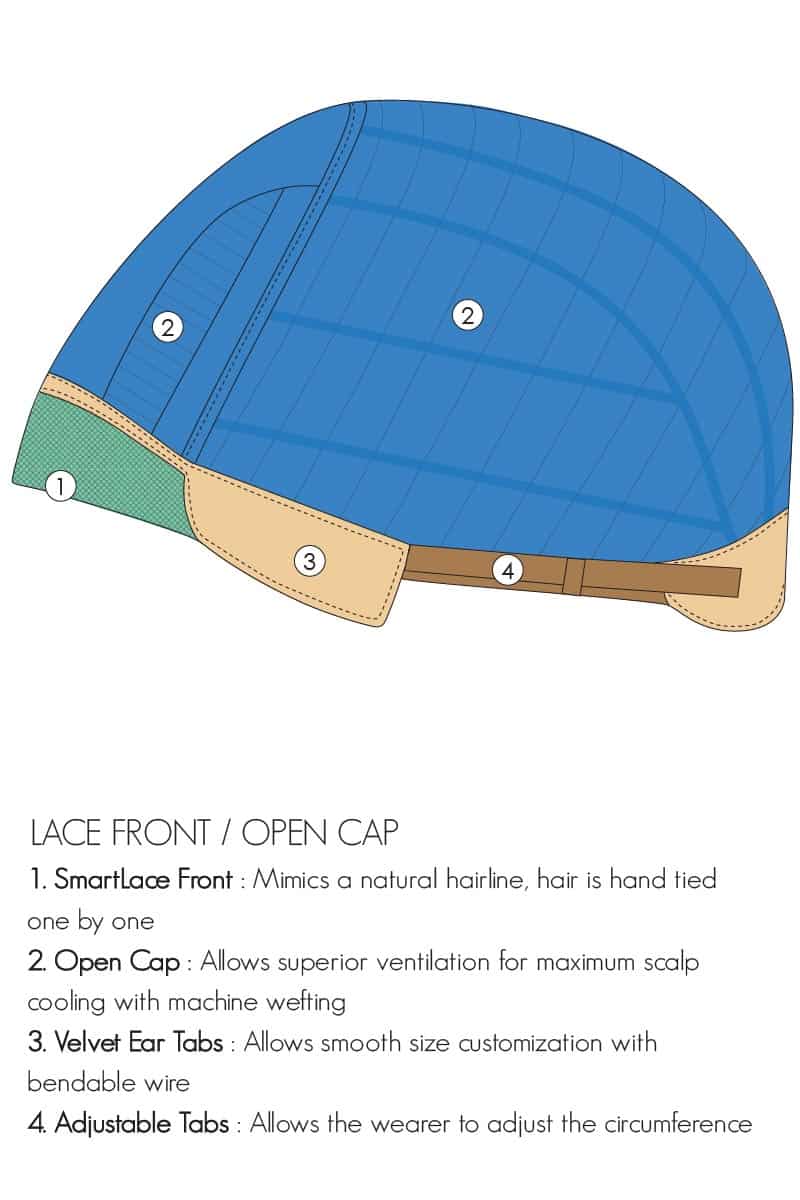

- Lace Front. What is a lace front? A piece of sheer lace mesh is located at the front of the wig cap. Hairs are individually hand-tied onto this very fine and delicate lace in order to create a more natural appearance. The lace will run across the front of the wig, from temple to temple, creating a lifelike hairline. The human hair fibers are attached to the lace in a non-uniform manner to give the appearance of natural hair growth and are almost indistinguishable from a biological hair hairline. Wig wearers can now adopt hairstyles where the hair is worn up or away from the face without fear of revealing an artificial or wiggy-looking hairline.

- Monofilament. What is a monofilament wig? Monofilament is a soft mesh that is mounted into the wig cap that can be placed at the front (part) crown or top. Human Hair fiber is attached to the monofilament and additional layers of monofilament can be added to provide enhanced comfort for the wearer. Human hair is hand-tied onto the monofilament strand by strand and knotted. The process is very labor-intensive and adds additional cost to the item but the end result is great. The individual strands now look like and move in the same way as biological hair. The hair can be parted in either direction and helps the wig look much more natural. The sheer mesh also lets your scalp show through for the most realistic look possible.

- Double Monofilament. What is a Double Monofilament Cap Wig? Double monofilament wigs include an extra layer of soft mesh that cushions the layer underneath to which hair is knotted. The result is that it feels even silkier and softer against the skin. Double Monofilament Wigs look and appear very natural and are a great choice for clients that have sensitive scalps.

- French Drawn Top. What is a French Drawn Top? A French Drawn top includes a third layer of monofilament that covers the entire inside of the wig cap for ultimate comfort.

- Open Wefting. What is a wefted wig cap? In some cases the monofilament component and the lace front component will make up only a part of the overall surface of the wig cap and the remaining area will be made up of a stretchy lace webbing. Human hair wefts are sewn onto the lace webbing to provide coverage across the remaining parts of the wig cap.

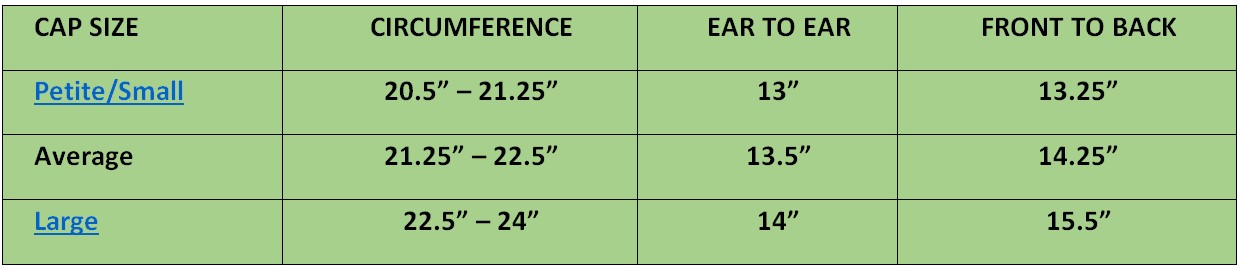

Almost 95% of all wigs sold are in average cap size although wig manufacturers have expanded their lines to include sizable selections of Small/Petite Sized as well as Large Sized. Wearers should be encouraged to measure their heads before ordering to ensure the perfect fit. The 3 measurements used in determining wig cap size are:

- Circumference. Measurement around the circumference of the head from the front hairline, behind the ear, to the nape of the neck, to the other ear, and back to the front hairline.

- Ear to Ear. Measurement from the point in front of one ear where the hairline ends, over the crown of the head, to the same point in front of the other ear.

- Front to Back. Measurement from the natural hairline in the front, over the crown of the head, to the bend in the back of the head where the head meets the top of the neck.

Most wigs are designed with an adjustable Velcro strap at the back to tighten and loosen for fit. These straps generally provide ½ inch to 1-inch play and allow Average sized caps to be almost one size fits all.

Ventilating a Wig Cap

A wig cap base is set onto a form (artificial head) and hairs are attached to the monofilament and lace front pieces of the wig cap by a procedure called knotting. The single, or “full V,” knot is the most common type of knot used and a wig maker will draw hair through the fine mesh with a ventilating needle and complete the knot to attach it. Knots are usually made with single hairs, while in the crown up to eight hairs may be knotted together. The process of knot tying on a wig is also known as ventilating. A full wig that is 100% hand-tied requires 30,000 to 40,000 knots, which take a total of about 40 hours of tying.

If a certain part of the wig is specified as wefted, a series of wefts are machine-stitched onto the ribs of the wig cap. The wefts are arranged horizontally, from side to side of the wig cap, and stitched close together to forms rows of hair. This process is faster than ventilating a wig and wefted parts generally make up the back of the wig where parting is not required. If the style calls for layering then wefts with different lengths of human hair are added strategically to give the appearance of different hair lengths

Styling Wavy/Curly Wigs

The ventilated wig is lightly dampened by moving a wet comb through the hair and rollers or pin curls are added to create the desired curl patterns. Manufacturers have prescribed styling for each wig and the curlers and pins are applied by way of a strict plan to ensure consistency from one individual item to the next. Once the rollers are applied successfully, the wig is placed in an oven at low heat to set the curls. The rollers/curlers are then removed, the wig brushed by hand, and then returned to the oven for a final setting.

Distribution: Wigs Boxed and Shipped

The wigs are tagged, inspected for quality at the factory and then boxed for shipping around the world. Owing to the fact that each style may have 25-30 color variations and a manufacturer’s collection may have over a hundred style options (2500-3000 style/color options) inventory management can be a challenge. Replenishment can take weeks from the factory and as a result marrying inventory with customer demand is a highly sophisticated process. Back Orders or out of stocks are frequent and are a frequent throughout the industry.

The Pros and Cons of Human Hair

Pros of Human Hair Wigs

Human hair wigs are still considered to be the most desirable and historically were preferable for the fiber being closely representative of the hair it was replacing. Advances in synthetic fiber over the past 20 years has narrowed the gap with human hair wigs and turned synthetic wigs into worthy competitors. Lace fronts and Monofilament caps are offered in both fibers and as a result there is no longer a huge and marked difference in terms of look, feel and movement. The differences are subtle but still distinct for discerning consumers.

- Natural Look: Wigs made from human hair look the most natural and are the closest to bio hair. Largely because they are natural hair. Human hair has a natural sheen and texture to it. It flows, settles, and moves like real hair and this is something that synthetic designers have struggled to perfect. Human hair wigs frizz, matt and tangle just like real hair does. While this often requires effort and time to maintain it is also mirrors the imperfections of real hair and as such denotes real, natural, and authentic. Remy hair, with the cuticles running in the same direction, is the closest alternative to bio hair and obviously comes with the best natural look.

- Natural Feel: Only a human hair wig feels like natural hair… again because it is. There are, of course, variations of natural feel with Remy Human Hair again proving to be the closest to the real thing. Human hair that is collected and sorted with cuticles aligned can be exquisitely soft to the touch and human hair with nonaligned cuticles requires additional processing that reduces life, feel and bounce. Sometimes it could just be the psychology that naturally feels better and synthetic is not natural.

- Styling: Human hair can be cut, colored, heated, and styled just like bio hair. Curl it, perm it, part it, twist it, or texturize it with curling irons, straightening irons and blow dryers. Add color or highlights! For those accustomed to spending hours in front of the mirror to create that ‘just right’ do, the human hair wig is a good fit. The styling options are endless and the human hair will mimic real hair to support limitless creations. Cutting a wig can be done but be reminded that it will never grow back and color-treatment by a professional colorist is doable but comes with similar perils.

- Heat Resistance: Human hair is very strong and can tolerate heat well. Wigdom is rife with horror stories of synthetic wig accidents and melted hair. Human hair will stand up better.

- Longevity: Human hair is more durable than its synthetic counterparts and as a result is longer lasting. It is estimated that human hair wigs will last 3 times longer and with the right care and maintenance can be worn up to 8 years. Good care and maintenance is the determining factor here. If you plan on wearing a wig every day, a human hair wig is likely the best choice

- Comfort: Although this is largely a determinant of the wig cap, it is often felt that human hair reflects light naturally and “breath” better than synthetic alternatives. The result is a cooler fit and less perspiration.

Images Shown Links: Blake by Jon Renau, Carrie by Jon Renau, Angie by Jon Renau

Cons of Human Hair Wigs

Human hair wigs may sound terrific, but as with anything, there are drawbacks, however few. Some of the drawbacks of human hair wigs are as follows.

- Price: Human hair wigs are higher priced without a doubt and this is the greatest impediment for most consumers. Prices for Human hair wigs at the LA Wig Company start at around $600. Sometimes the factor is 3-5 times versus a moderate-priced synthetic wig. If lace fronts and monofilament caps are requirements then this factor will be more like 2-4 times. The reason for the price difference is that the fiber sourcing, sorting, preparation, and manufacturing of human hair products is more involved. Remy human hair is an additional premium. It is often wise to consider the extended life of the human hair wig versus the synthetic wig (3 times) when calculating the true cost difference. At the end of the day, the cost difference over time may not be as big as imagined.

- Care: Like regular hair, human hair wigs require daily styling which can be time-consuming. The hours in front of the mirror, while pleasurable for some, may not be always possible. For those with fatigue as a result of chemotherapy, the practicality of a ‘shake and wear’ synthetic wig far outweighs the pleasure of styling. There is something to be said for a wig that holds its shape and styling and for many ‘convenience’ is the important factor when purchasing a wig.

- Long-Term Damage: Like anyone’s own natural hair, a wig made of human hair can become damaged and split over time from repeated brushing, heat styling, and color processing. This is why it is best not to color a wig very often, if ever. Unlike real hair, which can grow out and replenish itself, damaged hair on a wig is permanently damaged.

Summary

Human Hair wig making has gone global. Fiber is sourced in China and India, the wigs assembled in Indonesia and Thailand and sold to customers around the world including the United States. Large manufacturers such as Hairuwear, Aderans, and Jon Renau have developed fabulous designs, with vibrant color options, engineered wig caps, and the highest quality, ethically sourced human hair fiber. The end result is a product that brings style, sophistication and happiness to those who wear them.