There are more types of thread out there than most of us realize. From industrial screw thread to the kind used for sewing, they are designed to hold things together — from pipes to fabric. Learn about the different types of thread and how to use them.

During one long, sleepy summer, I embarked on several DIY projects, several of which involved sewing needles and fabric. My undertakings included making patio chair cushions and sewing 50 homemade bean bags for a kids’ camp. This was my first real foray into sewing.

I knew almost nothing about it, so the first order of business was to go to my local fabric store and get a crash course on the thread. I had no idea there were so many different types. I’ll pass along what I learned, along with a little more info I gleaned over the years, at least as it pertains to sewing thread.

Later, I learned that there are quite a number of other types of thread – machine screw threads, pipe thread, and computer programming varieties, to name a few.

Contents

- What Are the Different Types of Thread?

- Programming Threads

- What is a Thread Library?

- What Are the Different Types of Sewing Thread?

- A Note on Bobbin Thread

- What Factors Should You Consider When Choosing the Right Thread for a Project?

- What Are the Different Thicknesses of Sewing Thread?

- Tips for Using Embroidery Thread

- FAQs

What Are the Different Types of Thread?

Most people associate thread with sewing, but that’s not all it’s used for. There are so many other kinds, too, and they’re nothing like what you’d use with a needle and a bobbin. Here’s what you need to know about the many varieties of what we call thread.

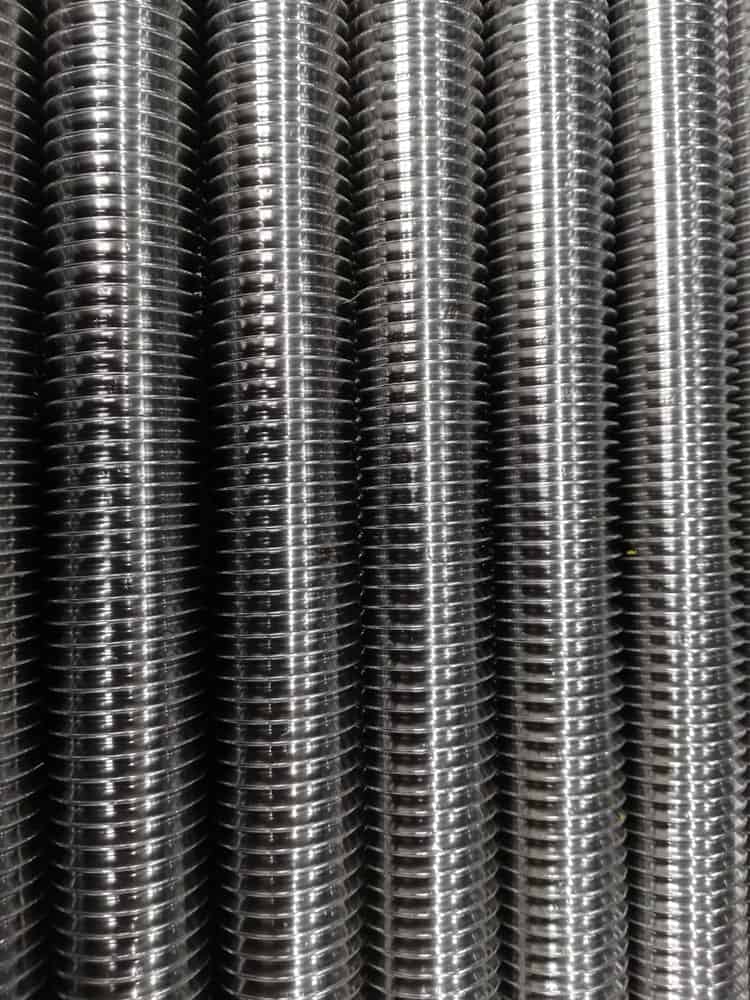

Screw Thread

A screw thread, often just referred to as a thread, is a helix-shaped (corkscrew-shaped) ridge that’s wrapped around a cone or a cylinder. When it’s wrapped around a cylinder, it’s called a straight thread. When wrapped around a cone, it’s called a tapered thread.

The screw thread is a crucial component when a screw is used as a threaded fastener or a simple machine. When used as fasteners, screw threads appear in nuts, bolts, plastic screws, machine screws, and wood screws. They’re also used in micrometers and lathes.

A screw thread can be internal or external. As its name suggests, an external thread is found on the outside of cylinders – on a screw, bolt, or stud. An internal thread, found on the inside of a cylinder, can be found on tapped holes and nuts.

The configuration of a screw thread is called thread form and consists of its crest, root, and flanks. If you’ve ever heard someone mention thread pitch, it’s the measurement of the distance between corresponding points on threads that are adjacent to each other.

When it comes to thread diameter/thread pitch combinations, there are a number of possibilities. here’s a quick summary of the different series.

- Coarse Thread. For general application nuts and bolts, the series UNC/UNRC is the most prevalent designation. Coarse thread offers several advantages: easy assembly, durability, and reduced possibility of cross-threading.

- Fine Thread. Designated as Series UNF/UNRF, this is most often used when precision is a must. Fine threads have better tensile strength than their coarse counterparts but require a longer engagement. Otherwise, stripping is likely.

- 8-Thread Series (8UN). Because it’s used for diameters of an inch or more, this is the go-to series for many ASTM standards: A193 B7, A193 B8/B8M, and A320

ASTM International is an organization that’s been around since 1898. It’s dedicated solely to establishing standards for technology and manufacturing that can be widely-recognized and easily-used.

Screw thread can be male or female, referred to as gender. Male thread (on the outside of a bolt) screws into the female thread (on the inside).

Pipe Thread

Pipe thread is used to connect hoses and pipes, either to each other or to other fixtures. It comes in tapered or straight varieties, although the tapered thread is the most common type. These threads can be tightened and compressed to form a seal, although usually, it’s not complete without a sealant. Each fitting is held together by a male thread and a female thread. National Pipe Tapered Thread (NPT thread) is the most oft-used tapered thread in North America. (More on that in just a bit).

Straight Thread

The straight thread holds in place a fitting that’s been done by mechanical joining. There are a few different types of straight pipe thread – National Pipe Straight Mechanical (NPSM), National Pipe Straight Hose, fire hose coupling, and a garden hose. The latter two are less common.

Metric Thread

Metric thread, officially called ISO (International Standards Organization) metric thread, is the most widely used thread type the world over, at least when it comes to the general-purpose screw thread.

Here’s a quick look at how metric fasteners work. A metric screw or bolt is sized in terms of diameter, pitch, and length. Measurements are provided in millimeters. For some coarse-threaded fasteners, the pitch is not specified.

Things can get a little confusing when trying to covert the metric measurements to inches. As mentioned earlier, pitch measures the distance between threads that are right next to each other. Inch measurements describe the number of threads per inch. Sometimes this is referred to as pitch, albeit erroneously. If you’re working with a metric fastener and you want to know its threads per inch, convert the pitch from millimeters to inches first. To do that, multiply by 0.03937, then divide 1 by the result.

Metric fasteners typically fall into one of two categories: coarse or fine. It may also be possible to find extra-fine varieties. Compared to the typical inch fastener, coarse metric threads are less coarse (spaced more closely together). Fine metric fasteners tend to be finer, or less so, than the “American” type, depending on the size.

BSP Thread

Common in Australia and other countries that use the metric system, BSP thread (British Standard Pipe) is given its classification based on trade size rather than diameter. It comes in two types:

- Parallel Thread (BSPP)- also called Rp or G

- Tapered Thread (BSPT)- also called R or Rc

Both kinds have an angle of 55 degrees. They also have the same pitch and shape (rounded valleys and peaks).

NPT Thread

NPT stands for National Pipe Thread, and it’s an American standard thread. But it goes by other names too. The male thread may be called MPT, NPT (M), or MNPT. As you might expect, the female variety is sometimes referred to as FPT, NPT (F), or FNPT. As with BSP thread, this type of thread gets its designation based on trade size instead of diameter.

Programming Threads

Another type of thread is used in the operation of central processing units (CPUs) in computing. These threads consist of an ID, stack, a set of registers, and a program counter. They contain sequences of instructions, and many applications require multiple threads. This model allows for faster response times and multi-tasking, leading to greater efficiency.

In the technology world, threads can take one of two forms: user-level and kernel level.

- User threads. As their name suggests, these threads are managed by users, rather than some other source. A user-level thread may be used by any operating system and can be application-specific. Since they don’t require kernel mode to operate, they can be more efficient to use.

- Kernel threads. These are operating system-managed (OS) threads run by the kernel, an OS core. They’re usually slower to create and execute than the user level variety, but they can be used for multiple processes or to employ a new thread when another is blocked.

What is a Thread Library?

Thread libraries are used in programming. Thread libraries make it possible for programmers to manage threads using an application programming interface (API). APIs are the components of remote servers responsible for receiving and responding to requests. Companies use them for their own internal operations or make them available as a platform for their customers. Threads work behind the scenes to executive a variety of processes. Today’s servers utilize three types of thread libraries:

- Java Pthreads

- Win32

- POSIX Pthreads

Thread libraries contain codes for creating and destroying threads and regulating how threads communicate with each other.

What Are the Different Types of Sewing Thread?

Sewing thread comes in several types. Each type is best suited for different purposes. Here’s a rundown of the various kinds and their applications so you know what to use for your next sewing project.

Cotton Thread

Cotton thread (or any thread that’s made from natural fibers, is weaker than some other types of thread. It’s good for delicate projects that use a material that is weaker than cotton. That way, if too much stress is placed on the seams, it will cause the thread to break, rather than tearing the fabric. A torn seam is much easier to repair.

Some people think the cotton thread should only be used on cotton fabrics, but that’s not necessarily the case. However, it is a good fit for quilting and patchwork projects.

Elastic Thread

Elastic threads are “stretchier” and thicker than other types. They’re most often used with jersey fabric, elastic, and anything that needs to have some “give.”

Elastic thread is so thick you can’t string it through a machine. Instead, you’ll need to put it in a bobbin in tandem with whatever regular thread you are using.

These threads are great for ruffles, stretchy waistbands, and shirring. Shirring involves loading the bobbin with elastic thread and loading the needle with some other thread variety. Using 3-4 mm stitches spaced 3/8-1/2″ apart, it’s possible to give the fabric a decorative look.

Polyester Thread

Also sometimes called “all-purpose” thread, polyester is great for most of your everyday projects. This thread is quite durable and has some give to it, making it ideal for anything that’s likely to go through a lot of wear and tear (kids’ clothes, anyone?). Polyester is also a good choice for knit and stretch fabrics. What makes it even more versatile is its suitability for machine and hand sewing alike.

Embroidery Thread

Embroidery threads come in a wide range of colors, so you can use them with just about any kind of home decor project, or anything else you want to give some extra style. But they are more versatile than many people realize. Embroidery threads are designed to pass through fabric frequently, so they’re more durable than some other threads. Another plus: these threads are relatively inexpensive.

Embroidery thread grades range from 30 to 60, and it’s available in a variety of materials for your machine-sewing or hand-sewing projects. Since it’s not twisted like some other types of threads are, it lies flat, making it a good substitute if you run out of your regular thread in the middle of a project. Embroidery threads are usually formed from 2 ply material, too (meaning they consist of 2 strands woven together).

One caveat: While you can use embroidery threads in lieu of another type, it’s important to make sure it’s strong enough for whatever you’re working on. A lot of these threads come in rayon, which, when wet, isn’t as strong as some other materials. So if you’re stitching workout clothes or anything meant for the outdoors, consider a different thread material. And, because it’s meant for decoration, embroidering thread may not be your best bet for heavy-duty projects or any fabric creations that will likely be subject to a good bit of wear and tear.

The good news: Most embroidering threads are sewing machine-friendly. Make sure your bobbin is fully-loaded before you secure it, and lower the feed dog if necessary. Especially if you’re just starting out, your task will be easier with an embroidery hoop.

Upholstery Thread

Because it’s made with durability in mind, upholstery thread is heavier than your everyday types. The key to having success with these threads is adjusting the tension on your machine. Many of these “industrial strength” threads are bonded with a special coating that prevents wear and tear caused by friction. They’re tough enough to be durable but delicate enough not to tear the fabric they hold in place.

Bonded nylon and bonded polyester are two of the most widely-used threads for upholstering. If you’re making cushions and the like for outdoor furniture, bonded polyester is a smart choice because it’s resistant to the sun’s UV rays. That means your outdoor decor won’t succumb as easily to fading and deterioration from weather elements. For just about everything else (that won’t be exposed to the sun, you can use bonded nylon.

Metallic Thread

Metallic thread is ideal for decorative stitching. Like many other types of thread, you can use it when sewing by hand as well as with a machine. Because of its shimmer, it’s ideal for embroidery and other decorative projects. You can even use it with a serger.

Many a sewist has experienced headaches with metallic thread, either because the thread was of poor quality or because they weren’t using the right type of needle. To keep hassles to a minimum, look for the thread that has these three components.

- Nylon core. The nylon core makes the thread stronger and less likely to become tangled.

- Paper coating. Top-notch metallic threads have a layer of rice paper over the core. This enhances the thread’s flexibility while making it more cohesive.

- Outer coating. This is a coating that protects the outer metallic layer of the thread. This reduces friction during sewing, making the thread less prone to becoming shredded or frayed as it’s pulled through a machine.

I mentioned earlier that a lot of sewing snafus happen with metallic threads because sewists aren’t using the right needle. For best results, use one designed for this type of thread. Its larger eye will minimize friction that occurs during the stitching process. You may also want to consider using a horizontal spool holder, as it will reduce tension on the spool, allowing the thread to “flow” into your machine more easily.

And if you’re using metallic threads in a serger to make decorative edges, try using it with a rolled hem setting in the upper topper. Or you can set your machine to a balanced hem setting and use the lower and upper toppers. You can change the stitch length to get the look you want.

Nylon Thread

Silk Thread is a smooth thread that can give your projects an elegant finish. You can use it when sewing by hand or with a machine. Some sewists like to use it for basting, buttonholes, finishing hems, and the like because it’s easy to work with and is relatively inconspicuous.

Despite its delicate look and feel, silk thread is actually pretty strong. You can bring out the best qualities of your silk thread by pairing it with an unlikely accessory: beeswax. You can pass the thread through the beeswax, then iron it (taking care not to scorch the thread). Ironing melts the beeswax, allowing the thread to pass even more smoothly through the fabric. This might sound like more work, but it will make the thread even more pliable, requiring less effort in the long run.

There are other creative ways to use silk thread. Sewists like it for topstitching and decorative stitching, too.

A Note on Bobbin Thread

Bobbin threads are durable, yet lightweight. They’re good for securing stitches and adding a little dimension to your work. Stitching from these threads is only visible from the back, so it doesn’t really matter what color threads you use because they don’t necessarily have to go with the topstitch.

What Factors Should You Consider When Choosing the Right Thread for a Project?

There are several things to consider when choosing the right kind of thread for a project, especially for crafts that require multiple threads.

Think about fabric properties. You’ll want to select threads that are a good fit for the fabric you’ve chosen. The thread you opt for should match the material in size and weight.

Another tip (this one is optional) recommended by sewists the world over is to use threads that match the fiber content of your material. That means using cotton with natural fibers, polyester with synthetics, and the like. However, you can still get good results without this approach.

Consider thread quality. As with most other things, when it comes to thread, you get what you pay for. Cheaper threads tend to be made from inferior materials and are especially prone to tangling, tearing, and unraveling. Though it will cost a little more up-front, choosing higher-end threads will allow you to enjoy the fruits of your labor longer.

Since the style and look you want to achieve are up to you, you have some leeway with color selections. In most cases, it’s a good idea to match the color of your fabric. But when making home decor or sewing appliques, a contrasting color may work better.

What Are the Different Thicknesses of Sewing Thread?

Thread sizes and thickness are written as #/#. The first numeral tells you the thread size according to the Gauze Count STandard. These measurements range from 30 to 60, and a larger number indicates a finer thread. Hence, 60 is thinner than 40. The second number reflects the number of strands (plies) that are twisted together. A 50/2 thread consisted of two intertwined strands, while a 50/3 has three interwoven strands. And both have the same thickness (or lack thereof, since the Gauze Count number is pretty high).

Some labels on threads are misleading because they classify the gauze count as the weight of the thread. Here’s an example. A 40/2 and a 40/3 might both be marked as 40 wt. However, the 40/3 thread is considerably heavier because it consists of three plies instead of two. Therefore, it’s best to go by both numbers instead of the general weight label. The weight system is more prevalent in the United States. Despite the confusion, many US-based sewists prefer this way of measuring.

The International Organization for Standardization recognizes a different method of measurement called Tex (probably because it originated in the textile industry). This system is gaining popularity, probably because it’s pretty straightforward. The higher the number, the heavier the thread.

Essentially, the starting point for the Tex method is 1,000 meters per gram. If 1,000 meters of thread measure one gram on the scale, then it is labeled Tex 1. If 1,000 meters of another kind of thread weigh 30 grams, the length of it is marked Tex 30. These variations can be expected because some materials weigh considerably more than others, even if the corresponding threads are the same diameter.

Tips for Using Embroidery Thread

If you’ve had any experience with embroidering, then you know it’s not always the easiest task. You want the decorative touches on your crafting projects to look just right. Here are some tips to help you do that.

- Embroidery threads consist of either synthetic or natural fibers. The most frequently-used materials are rayon, cotton, silk, and polyester. There are specialty threads, too, intended for specific uses. When it comes to synthetics, polyester and rayon threads are the most widely-available.

- Keep in mind that while metallic thread looks awesome, it tends to break easily. To reduce the risk of that happening, run your machine at a slower speed. If time is of the essence, it’s better to choose a different thread than to try to rush through with the shimmery stuff.

- Make sure the thread’s weight can hold up to the project, as well as any wear and tear it might endure after it’s complete. Most sewists also try to stay away from old thread, but if you have some older threads on hand and still want to use them, do so with older fabric. Many people who sew advise against using older thread on new fabric. Plus, it’s helpful to use threads of the same material as the fabric you are working with.

- Consider Digitized Design Specifications. When it comes to embroidery, most digitized designs are meant for 40 weight thread.

- Test Your Thread. You can do this with a simple test using your hands. Pass the thread between your fingers. Give it a few tugs to see how it holds up. Place it next to your fabric to see how it looks.

FAQs

What’s the best thread for a sewing machine?

The best thread for a machine is one that is high quality. Cheap threads may damage the tension disks in your sewing machine. While it may cost a little more up-front, it’s definitely worth it, in the long run, to pay more for the thread.

It will enhance the longevity of your machine and your projects. Some obvious signs that a thread is subpar include looking frayed or shedding fibers. If you’re having issues with your machine, try changing the needle first. If problems persist, the thread is probably the culprit.

Are there any threads that should not be used in a machine?

Yes. Some decorative threads are made only for hand-sewing and are not intended to be used in a sewing machine. These threads come in a variety of materials. In addition to not being machine-friendly, they should also not be used for manual sewing that involves joining fabrics. These threads are only meant for putting finishing touches on home decor and similar pieces.

What are spaced threads?

This type of thread is intended to form its own thread in pre-drilled holes. You’ll most likely find this type in wood screws, coach screws, and self-tapping screws?

What are some other measurements pertaining to screw threads?

There are a few other measurements that relate to screw threads. Minor diameter is the smallest diameter of a screw thread and depends on its thickness. Outer diameter refers to a measurement of a pipe’s outside edges. (It may also be called outside diameter or external diameter). The effective diameter is another way of saying pitch diameter.

What is a pitch gauge?

Also called a screw gauge or a thread gauge, a pitch gauge measures the lead or pitch of a screw thread. The tool makes it possible to quickly figure out the profile of a screw thread. Plus, it can be a real time-saver since the user doesn’t have to calculate the pitch. However, the gauge is not a precision instrument.

What Is pitch diameter?

Pitch diameter is something all threads have in common. It’s the distance from one pitch line to another that’s 180° around.

What is an acme thread?

This thread type was primarily used on tools designed to perform especially heavy work. In today’s world, this thread form is used mostly for CNC systems, jack screws, lead screws, and industrial tasks that require power transmission and heavy torque.

References:

Treasurie: Sewing Thread Types: Best Thread for your Project

SewDaily: My Favorite Tool for Hand Sewing: Some of that Beeswax

Heirloom Creations: Making the Most with Metal Threads

Sewing is Cool: Thread Uses: Can I Use Embroidery Thread For Regular Sewing?

Online Fabric Store: How to Use Elastic Thread

We All Sew: How to Create Shirring with Elastic Thread

Amazon: The Best Bobbin Sewing Thread for Embroidery, Quilting, and More

Cornell: The Threads Library

UIC: Threads

The Spruce Crafts: The Differences in Sewing Thread

Melco: How To Choose The Right Embroidery Thread

Fastener Mart: Understanding Metric Fasteners

Accurate Screw Machine: Can You Explain Some Basic Screw and Thread Terms?